Drybox System

Supershield Drybox System meets below-ground structure needs

Supershield's DRYBOX system ensures that the structure is completely waterproofed. It makes the concrete structure impermeable to water not only through the concrete matrix but also through the joints, installation parts, service penetrations, cracks, and other defects within the concrete.

The DRYBOX System has a full range of Supershield Crystalline Waterproofing Admixtures, which waterproof the whole concrete mass right from the start. It also has a complete spectrum of products designed for construction joints, penetrations, and crack limits, such as hydrophilic sealants and profiles, waterstops in different material qualities, and sealing tapes, depending on the type and location of the joint and its requirements.

Key Advantages

Time is saved during the design and construction stages because complex detailing and installation are no longer required.

The compatibility of multiple products used in the construction of waterproof concrete is ensured.

In comparison to other systems, it is less expensive.

The total amount of material used on the job site is decreased.

Work is completed faster and with less environmental impact while maintaining the durability goal.

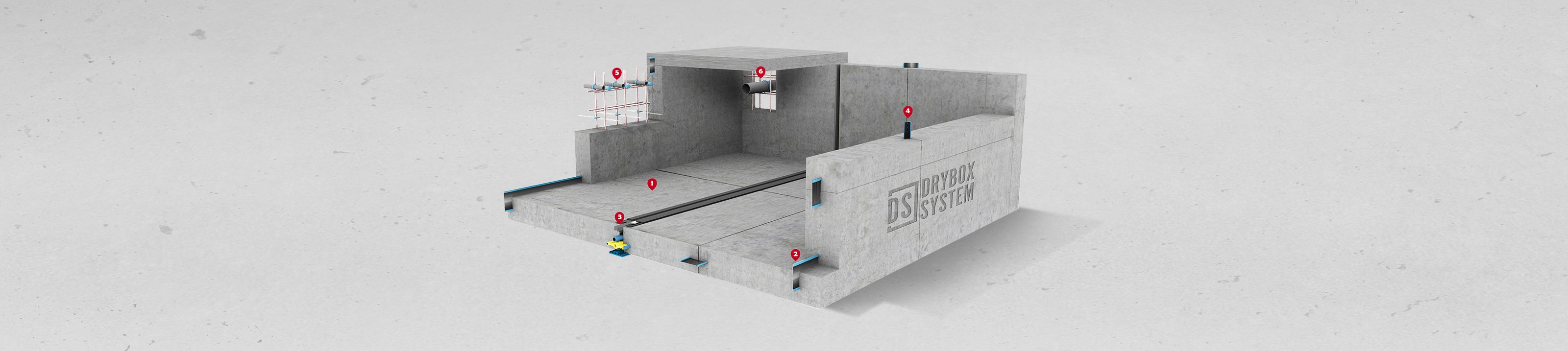

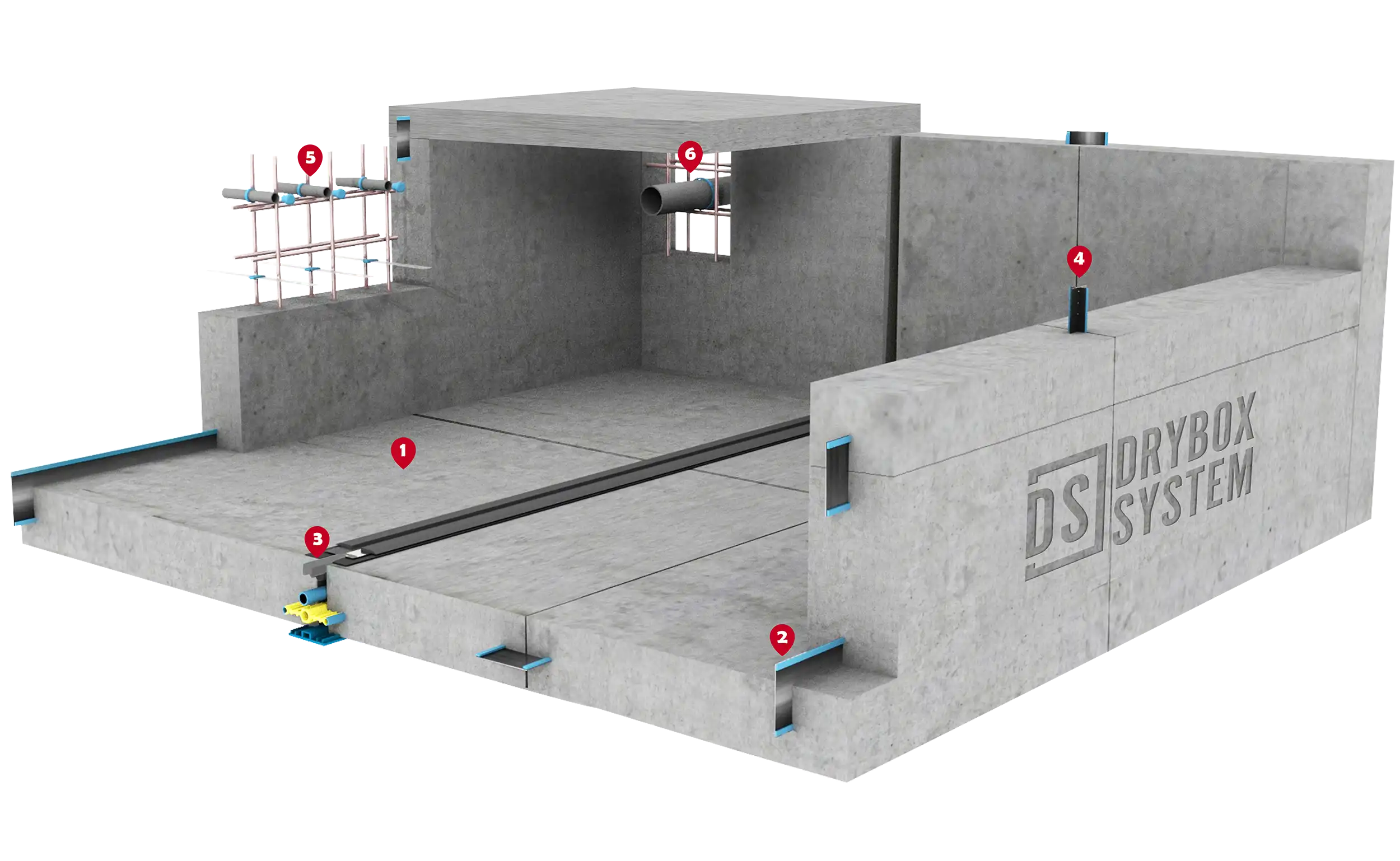

Supershield DRYBOX System Components

123456

1234561. WATERTIGHT CONCRETE

2. CONSTRUCTION JOINTS

3. EXPANSION JOINTS

4. PROGRAMMED CRACKS

5. FORMWORK SPACERS

6. PIPE PENETRATIONS

1. WATERTIGHT CONCRETE

Supershield’s DRYBOX System achieves waterproof concrete with Supershield’s Crystalline Waterproofing Admixtures, which take advantage of concrete’s nature to create an integral reaction that permanently waterproofs and protects the concrete by sealing its pores and capillaries with a non-soluble, highly resistant needle-like crystalline structure that becomes an integral part of the concrete.

This crystalline structure occurs where moisture is present, so at any later stage, if cracks form due to settling or shrinkage, the incoming water triggers the crystallization process and additional crystals begin to grow, and it has the ability to self-heal cracks.

Products Used

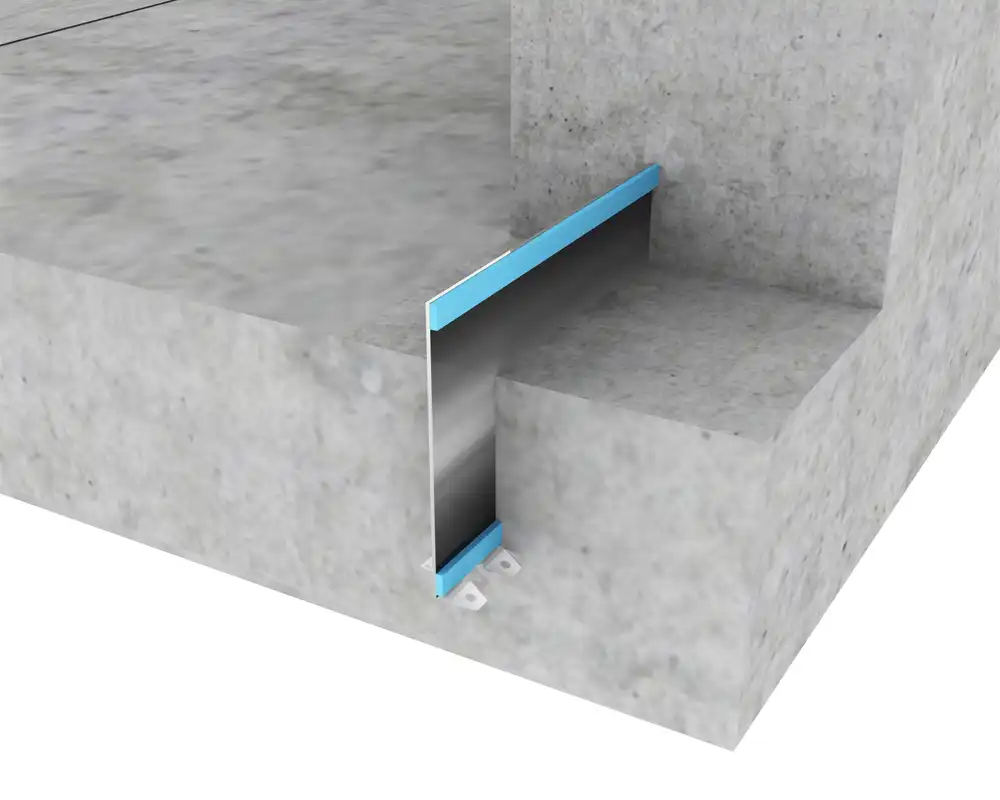

2. CONSTRUCTION JOINTS

Construction Joints are introduced in order to facilitate the shrinkage caused due to the large displacements . These are the most likely areas which can result in water ingress. Due to the nature of concrete and reinforced concrete, structures must always be built divided into sections by forming joints. Waterstops are necessary products used for the sealing of construction joints. Waterstops should be used to prevent water transmission at joints and must be installed in all joints to produce a closed joint sealing system.

Steel Waterstops for Sealing Construction Joints

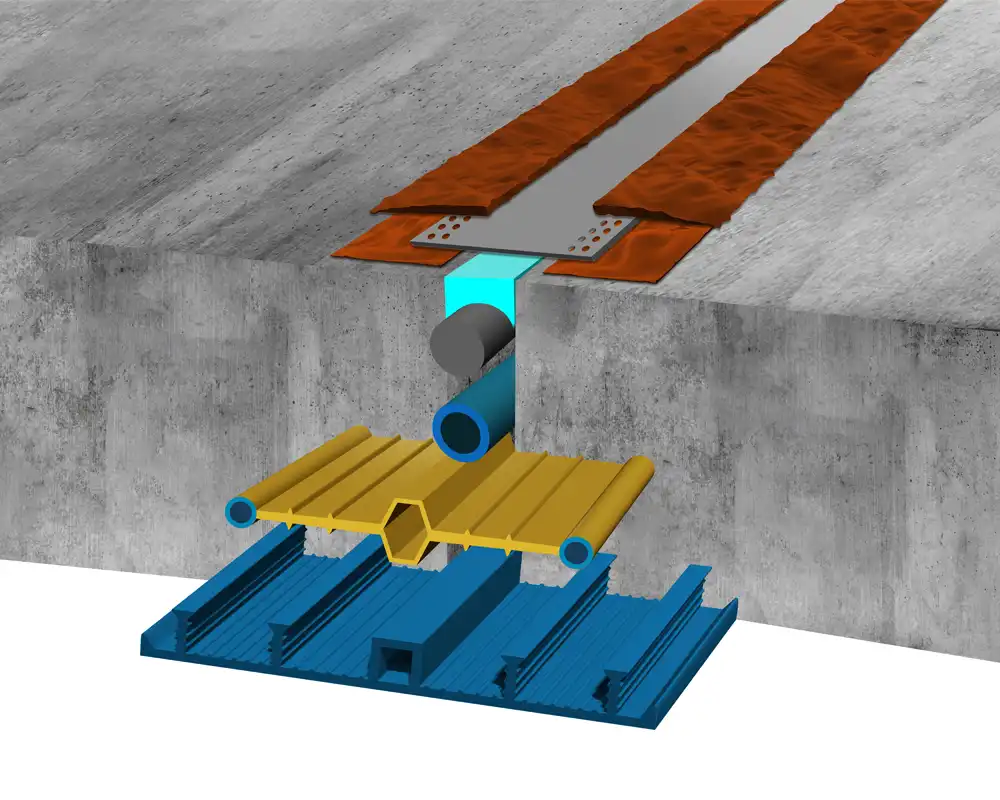

3. EXPANSION JOINTS

Special attention should be given to the use of waterstops at movement joints. Movement joints are necessary because of movement in the structure as a result of settlement, traffic loads, shrinkage, or other causes. In addition to the function of the waterstops to act as a waterproofing seal in the joint, the waterstop should allow the sections to move independently of each other – without restriction and free from tension.

Swellable Profiles and Sealants for Expansion Joints

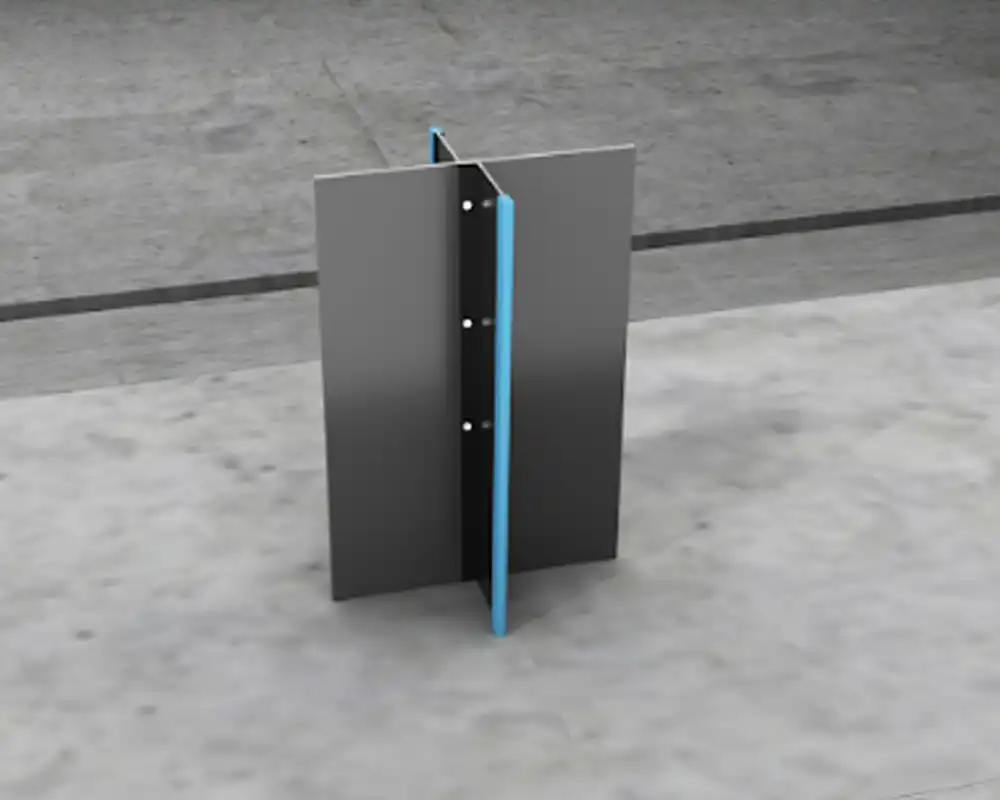

4. PROGRAMMED CRACKS

Special attention should be given to the use of waterstops at movement joints. Programmed Cracks are planned cracks that add a weak point in the concrete slab and force the small crack to form along the cut rather than appear as a random crack at some more obvious point, and this also allows the release of the additional stress developed in the concrete.

Products for Inducing Programmed Cracks

5. FORMWORK SPACERS

Supershield SWELLPLUG and SWELLRING are easy and secure ways of sealing around all types of formwork spacers (Round and Square). Different sizes are available for the most common spacers. The SWELLPLUG seals the inner ring, whereas the SWELLRING seals around the outside of the spacer.

Swellable Plugs and Rings for Formwork Spacers

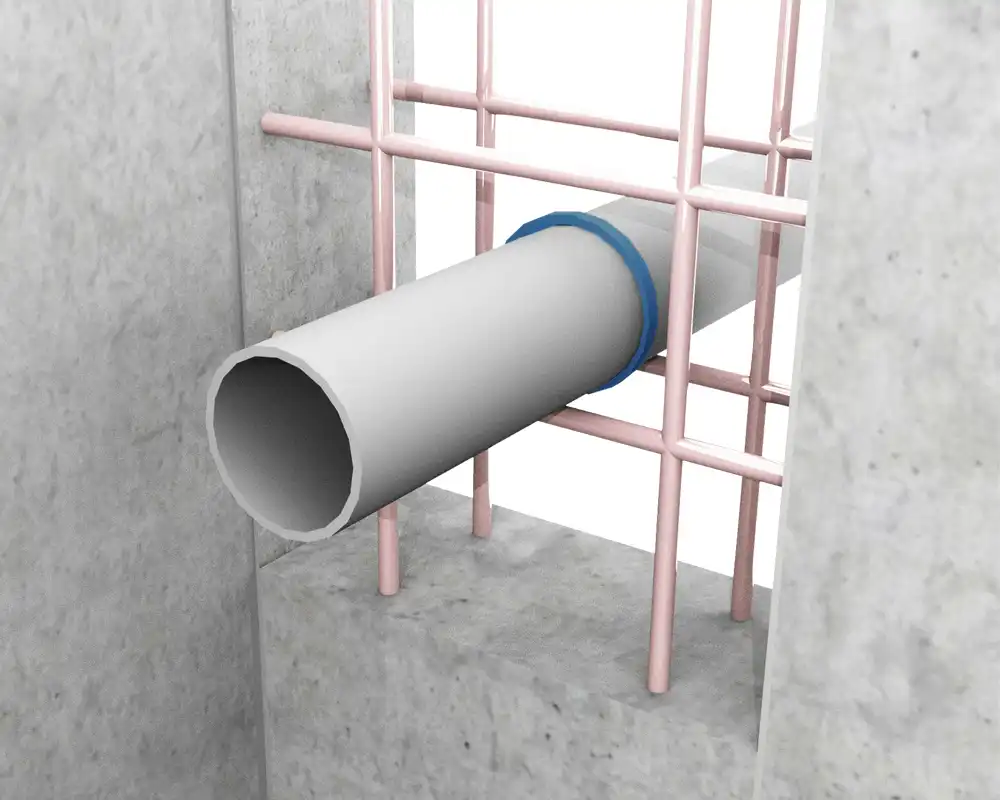

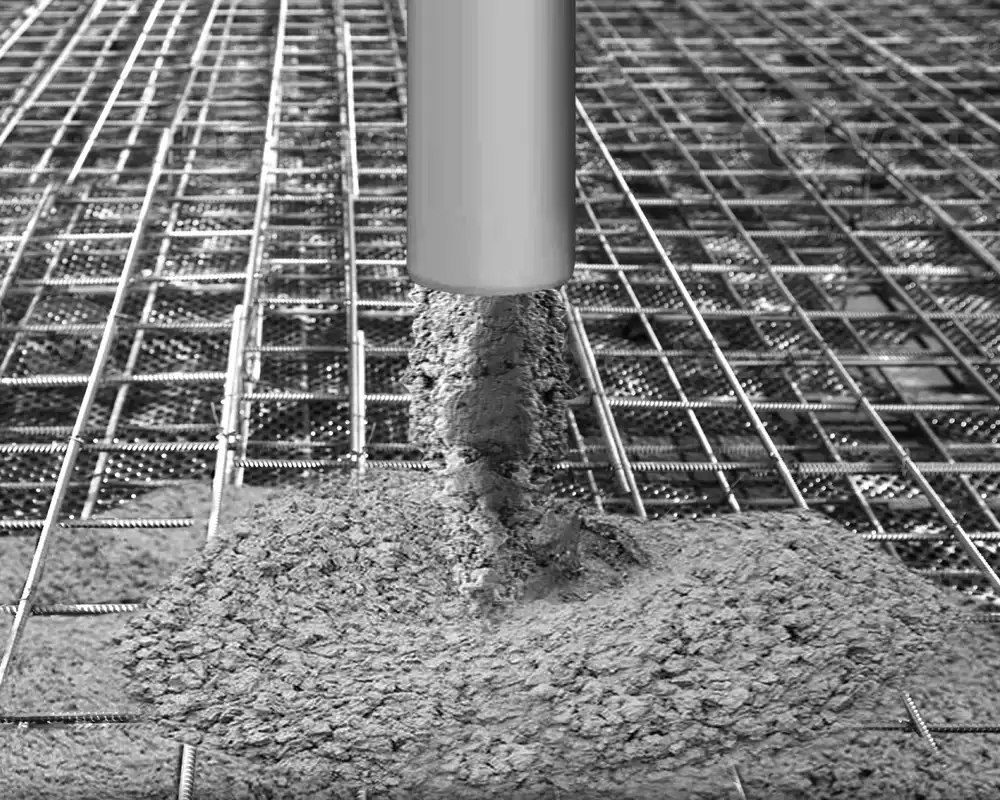

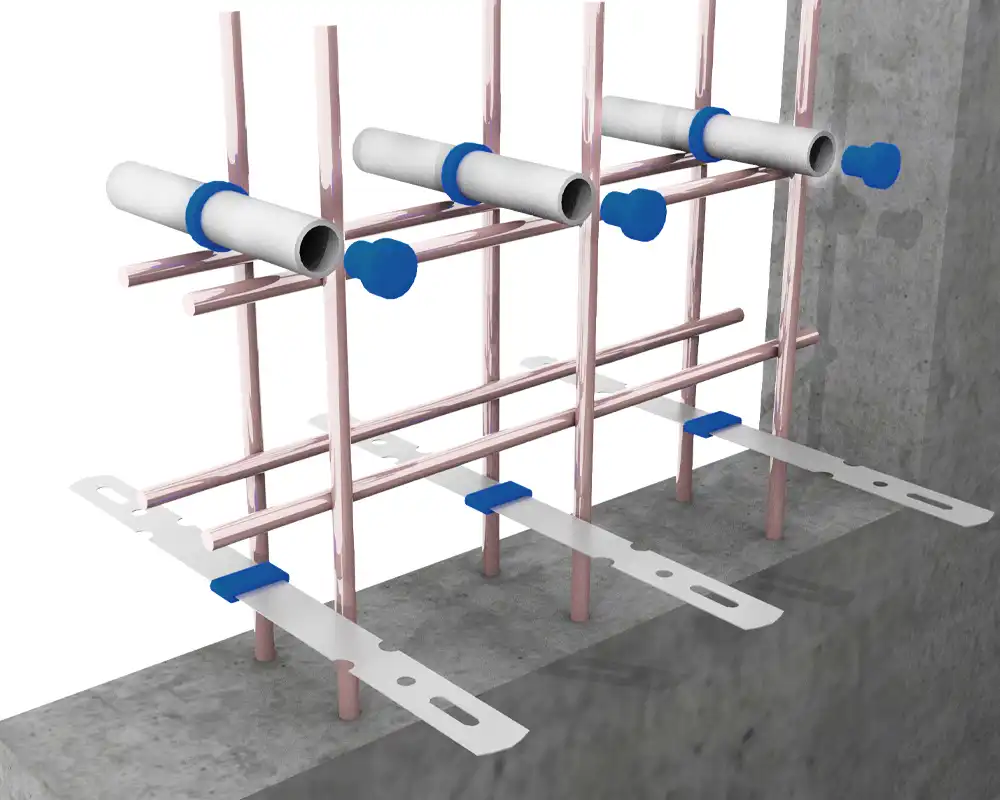

6. PIPE PENETRATIONS

Supershield SWELLSTOP can seal the penetration and isolation joints between different materials very easily. It can be bonded to many different substrates as well as concrete, including stone, metals, and many plastics.